- Home

- Profile

-

Products

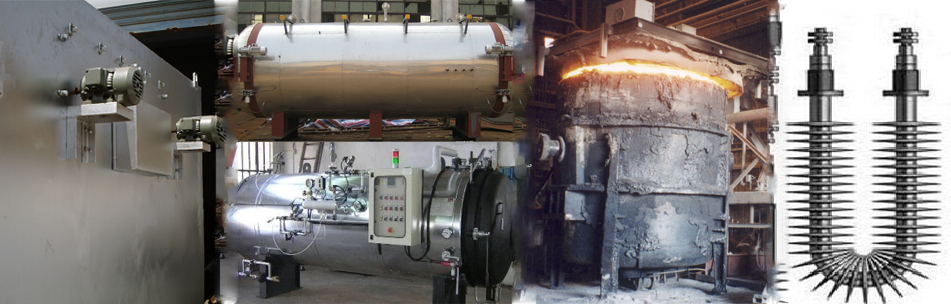

- Furnaces

- Solution Treatment Furnace

- Solution Annealing Furnace

- Bogie Heath Furnace

- Chamber Furnace

- Heat Treatment Furnace

- Roldown Hearth Furnace

- Rotary Hearth Furnace

- Continuous Furnace

- Aluminium Melting Furnace

- Aluminium Holding Furnace

- Aluminium Coils Furnace

- Experimental Furnace

- Pit Furnace

- Box Type Furnace

- Hot Dip Galvanising Furnace

- Crucible Melting Furnace

- Salt Bath Furnace

- Bell Type Furnace

- Mesh Belt Furnace

- Seam Vessel Annealing Furnace

- Vacuum Furnace

- Ovens

- Incinerators

- Boilers

- Dryers

- Autoclaves

- Ladle Pre Heater

- Industrial Bath

- Fuel Handling System

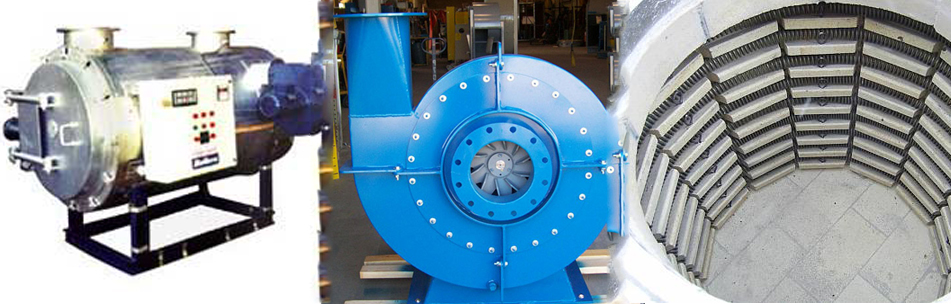

- Heaters

- Flange Immersion Heater

- Air Duct Heater

- Storage Tank Heater

- Electrical Process Heater

- Circulation Heater

- Boiler Heater

- Pipe Heater

- Bobbin Heater

- Tubular Heater

- Finned Tubular Heater

- Straight Finned Heater

- U/M Finned Heater

- Stripe Heater

- Finned Stripe Heater

- Ceramic Bend Heater

- Furnaces

- Hot Air Generator

- Blowers

- Control Pannel

- Coils

- Recuperators

- Heat Exchenger

- Ignition Transformer

- Beru Ignition Transformers

- Fida Ignition Transformer

- Cofi Ignition Transformer

- Brahma Ignition Transformer

- Nec Make Ignition Transformers

- Ignition Transformers

- Ignition Transformers For Oil Burners

- Danfoss Ignition Transformers

- Honeywell Ignition Transformer

- Siemens Ignition Transformer

- Danfoss Ignition Units

- Treviso Italy Ignition Transformer

- Oil Burner Nozzles

- Photocells and U.V.Cells

- Burner Motors and Blower Wheels

- Solenoid Valves and Coils

- Suntec Oil Burner Pumps

- Sequence Controllerss

- Diffuser Plates and Blast Tubes

- Oil and Gas Filters

- Ignition Cable

- Ignition Electrodes

- Pressure Switches and Solenoid Valves

- Oil Pump Coupling

- Burner Spare Parts

- Ecoflam Oil And Gas Burners

- Aspee Water Pump

- Krom schroder gas combustion controls

- Riello Oil & Gas Burner

- Torque Rotary Actuator Motor

- Siemens Compact Universal Controller

- Kromschroder Gas Burners

- Ecoflame Burner Spare Parts

- Wesman Burner Spare Parts

- Shineui Pressure Switches

- Sookook Oil and Gas Burners

- Valves

- Baltur Oil and Gas Burners

- Weishaput Burner Spare

- Bentone Burners and Spare Parts

- Honeywell Flame Detectors

- Pressure Regulator

- Choke beans/ Bean chokes

- Bakery oven oil and gas burner

- Flame sensors and photo cells

- Heating pumping unit

- Ignition Electrode

- Burner Servo Motors

- Danfoss Burner Components

- Oilon Burner Spare

- Electrogas safety solenoid valves

- Siemens Control Box

- Cumituff Ignition Electrodes

- Riello burner spare parts

- Thermax boiler spare parts

- Solenoid Valves

- Gas Burner Parts

- Dungs Gas Combustion Controls